TEKTRO & TRP lab and field testing to the max

Before a new brake is launched on the market, the entire system must undergo multiple standardized test runs. For this purpose, TEKTRO and TRP have their own test laboratories and tests, with their own team of technicians and engineers responsible for the set-up and running of each test. It is tested according to the international standards of the bicycle industry, for example DIN 79100. . In addition, practical tests are carried out permanently with bicycles of various categories. In the cargo area with system weights of 180 kilograms.

QUALITY CONTROL

Every brake goes through strict tests before it is delivered to a customer – every single brake!

- 100% quality test – for every single hydraulic disc brake produced by TEKTRO

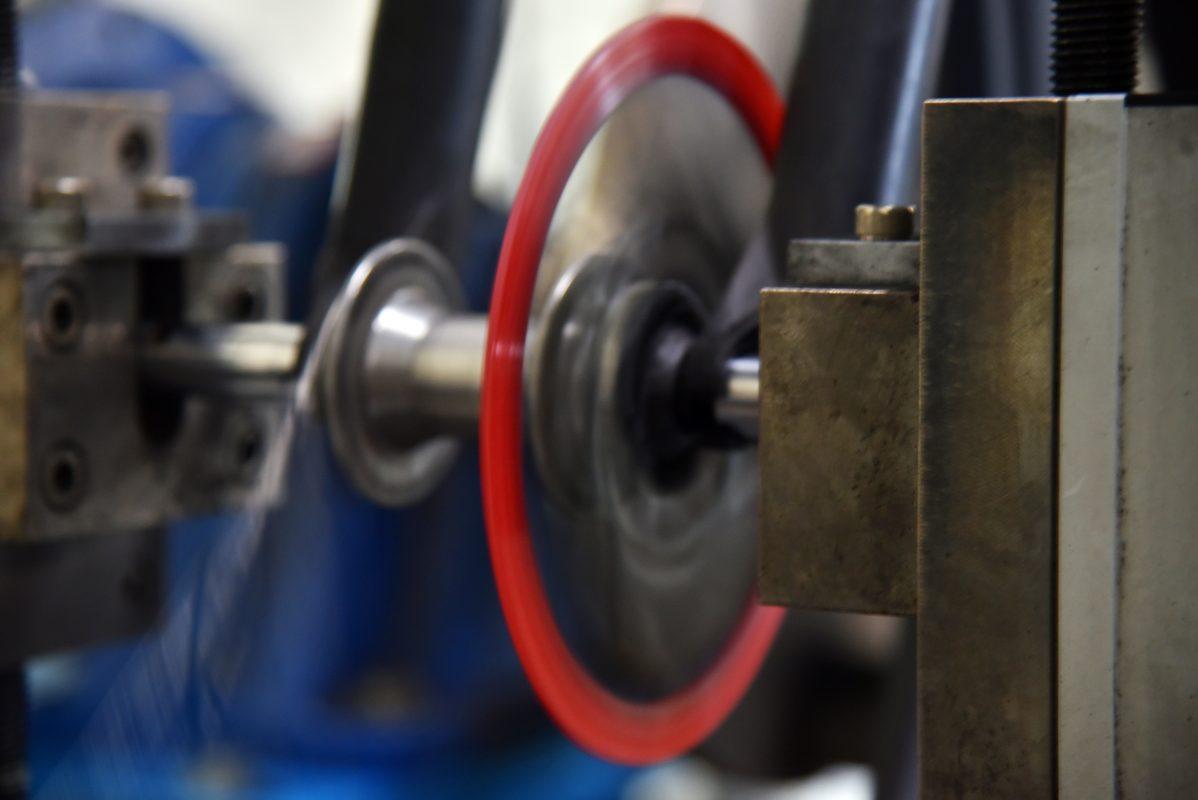

- TEKTRO has a test team of 28 people and 300 test benches within the production facility

- All test benches are designed and built specifically for TEKTRO’s requirements

- The oil pressure of each brake is tested for 8:45 min – the lever is pulled 250 times with a fixed load during this time

- The capacity for quality testing is close to 10,000 brakes per day